At ICARVISIONS, we are committed to delivering products that meet stringent quality standards. To ensure this, we implement the GB/T 2828.1-2012 standard for sampling inspection by attributes, a proven method aligned with international practices (equivalent to ISO 2859-1).

Background Information of GB/T 2828.1-2012

GB/T 2828.1-2012, which is the Chinese national standard equivalent to ISO 2859-1:1999. It outlines the sampling procedures for inspection by attributes, mainly used for acceptance quality limit (AQL)-based sampling plans.

Here are the key points of GB/T 2828.1-2012:

Purpose

It's designed for lot-by-lot inspection in a wide range of industries. The focus is on attribute data (pass/fail, defective/non-defective).

Inspection Levels

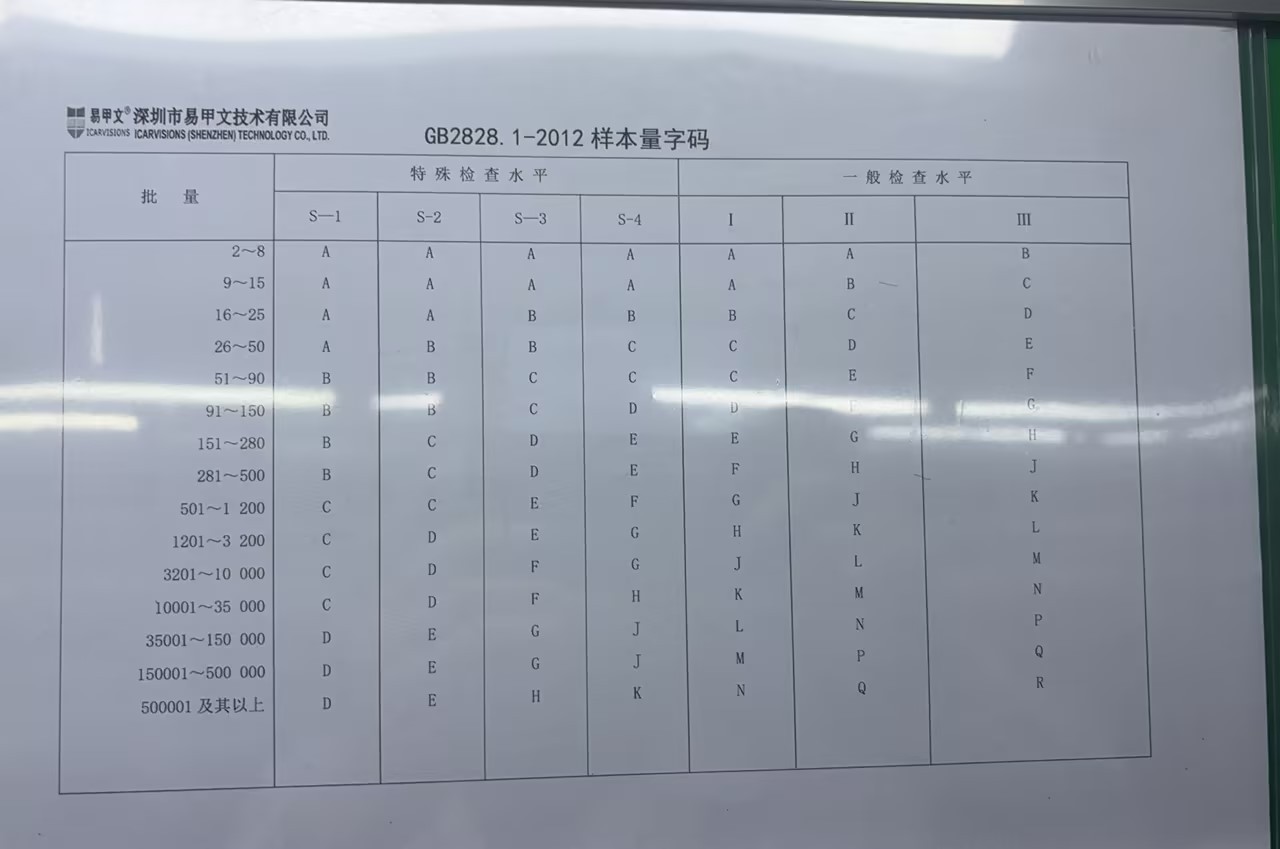

There are three general inspection levels:

I (reduced inspection)

II (normal inspection) → most commonly used

III (tightened inspection)

And four special inspection levels (S-1 to S-4) used for smaller sample sizes.

GB/T 2828.1-2012-ICARVISIONS

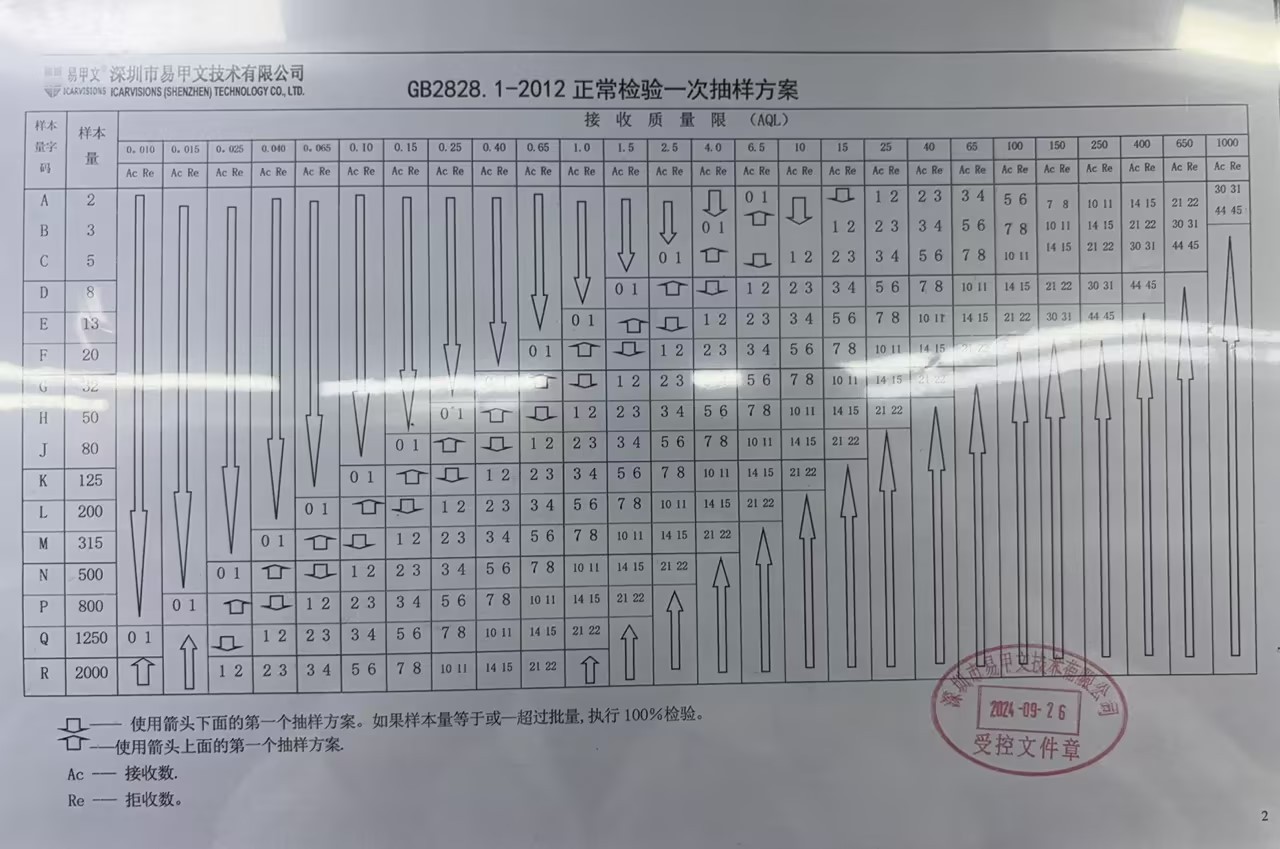

AQL (Acceptance Quality Limit)

AQL is the maximum percentage of defective items that can be considered acceptable as a process average. You choose the AQL value (e.g., 1.0%, 2.5%, etc.) based on the acceptable risk for your application.

AQL-ICARVISIONS

Sampling Plan

You use the sample size code letter (based on lot size and inspection level) to find:

Sample size

Acceptance (Ac) and Rejection (Re) numbers

This is done using standard tables provided in the standard (like Table 1 and Table 2-A/2-B/2-C).

Why We Use Sampling Inspection

In high-volume production, inspecting every unit is not always practical. Instead, we apply a sampling-based quality inspection process that enables us to assess product quality effectively and efficiently. This method ensures confidence in our output without compromising production flow.

Inspection Level: General Level II

We adopt General Inspection Level II, which is the standard level used for most product inspections. This level provides a balanced sample size that is large enough to detect quality issues reliably, while remaining efficient for ongoing production.

AQL 0.65% – Our Standard for Acceptable Quality

We set our Acceptance Quality Limit (AQL) at 0.65%. This means that during inspection, we accept a batch only if the number of defective units is within the acceptable threshold defined by this AQL level. AQL 0.65% reflects our commitment to strict quality requirements, especially for components and products where reliability is critical.

For example:

If a production batch contains 1,200 units, under Level II with AQL 0.65%, the sample size would be 80 units.

According to the standard’s sampling plan, the acceptance number (Ac) might be 2, and the rejection number (Re) would be 3.

This means: if 2 or fewer defective items are found, the batch passes inspection. If 3 or more are found, the batch is rejected and reviewed.

How the Process Works

Determine the batch size for inspection

Select the sample size code letter using Level II tables

Inspect the required number of units from the batch

Make a pass/fail decision based on the AQL 0.65% acceptance/rejection criteria

Customer Benefits

Tighter quality control through stricter AQL limits

Consistent performance and reliability of delivered products

Fewer defects in the field, reducing after-sales service and improving customer satisfaction

Transparency and traceability in our inspection procedures

By applying GB/T 2828.1-2012 Level II with AQL 0.65%, we demonstrate our dedication to delivering high-quality, dependable products. This quality control approach ensures that our customers receive goods that meet their expectations — every time.

Icarvisions.com

Icarvisions.com Español

Español português

português 简体中文

简体中文 繁體中文

繁體中文 Deutsch

Deutsch Français

Français 日本語

日本語 한국어

한국어 بالعربية

بالعربية TÜRKÇE

TÜRKÇE русский

русский English

English

Contact Us

Questions or comments? Please fill out the form below, send a quick message, or call us. We love to hear from you!